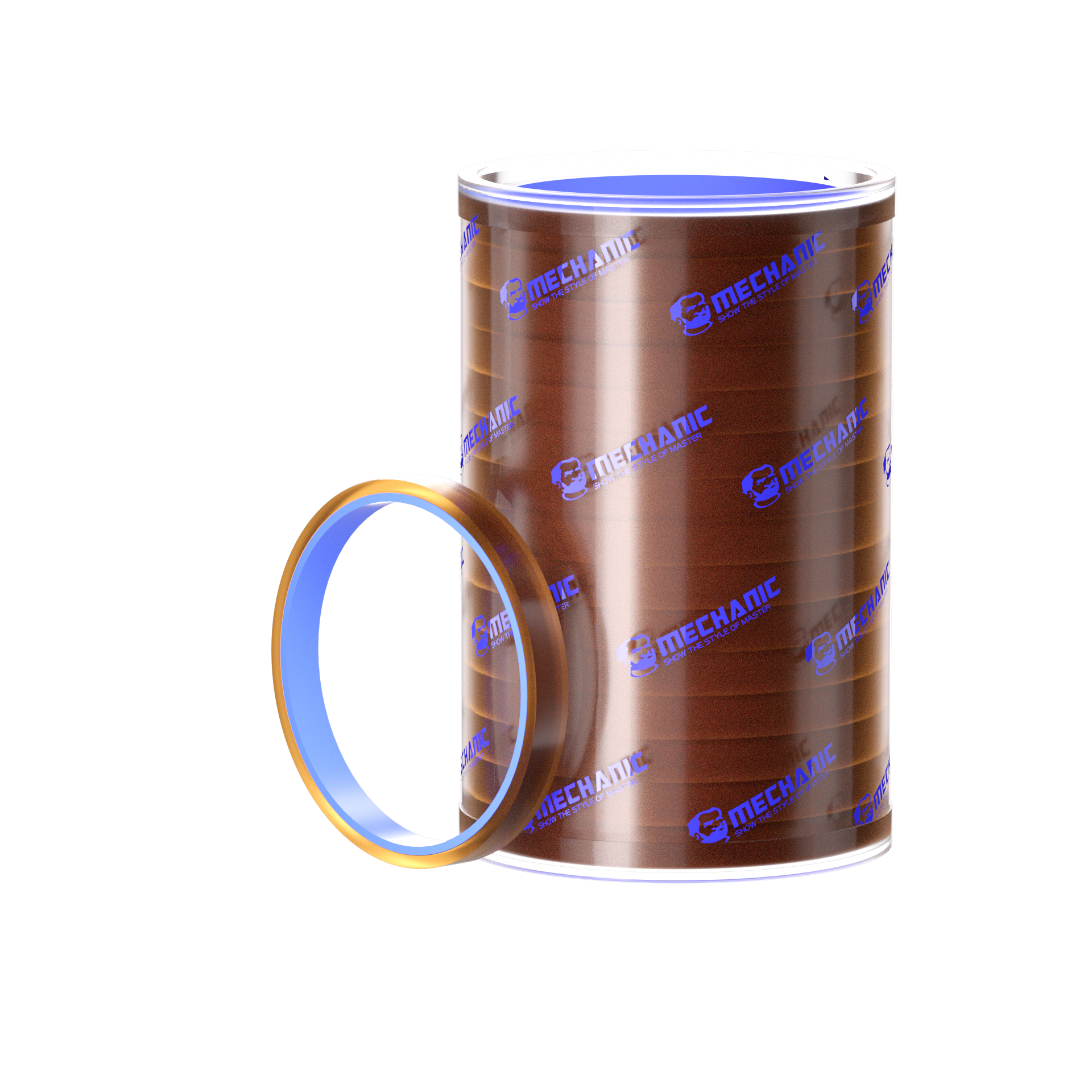

Mechanic Heat Resistant Tape high temperature protection

₱80.00

Out of stock

Mechanic Heat Resistant Tape high temperature protection

Heat-resistant tapes for mechanical applications are available in a variety of materials, each suited for different temperature ranges and specific uses, from insulating wires to wrapping exhaust pipes

. Brands like Mechanic and 3M offer specific products for electronics, automotive, and industrial uses.

Types of high-temperature tape

Fiberglass tape: Woven from fiberglass fibers, this material has very high tensile strength and offers exceptional resistance to heat, chemicals, and abrasion. It is often used for insulating pipes, high-temperature duct sealing, and exhaust wrapping.

Aluminum foil/glass cloth tape: This tape features a thermally conductive and reflective aluminum backing with a fiberglass cloth reinforcement. The foil reflects radiant heat, while the glass cloth provides strength. This material is excellent for heat shielding applications in aerospace, automotive, and general industry.

Polyimide (Kapton) tape: This tape is thin, lightweight, and extremely durable, with exceptional thermal stability that can withstand temperatures over 400°C ($752^\circ$F). Polyimide tape is a preferred choice for electrical insulation in electronics, especially during soldering and other high-temperature manufacturing processes.

Silicone tape: Used for applications requiring flexibility and sealing, silicone tape can withstand a wide temperature range, typically from -60°C to over 300°C. It is often used for electrical and plumbing insulation, and some self-fusing varieties are excellent for creating air- and water-tight seals.

Teflon (PTFE) tape: Known for its non-stick properties and corrosion resistance, PTFE tape is a reliable solution for heat sealing, insulation, and anti-adhesive applications. It can withstand temperatures between -180°C and 260°C.

Common mechanical applications

Exhaust pipe wrapping: Fiberglass or ceramic exhaust wraps are commonly used to insulate exhaust pipes and headers. This reduces under-hood temperatures, protects nearby components, and improves engine efficiency.

Electronics repair: Polyimide tape is essential for repairing electronics, such as insulating and masking sensitive components on printed circuit boards (PCBs) during soldering and heat-intensive repairs.

Automotive wiring: In engine compartments, heat-resistant tape is used to bundle and wrap wiring harnesses, protecting the electrical system from the extreme heat produced by the engine.

Welding and soldering: High-temperature masking tape, such as glass cloth or aluminum foil tape, can be used to temporarily protect surfaces from the heat of welding and soldering.

High-temperature masking: Polyester and polyimide tapes are used to mask parts before high-temperature processes like powder coating or oven curing.

Where to buy mechanic heat-resistant tape

Online marketplaces: Websites like Shopee and Lazada offer a wide range of heat-resistant tapes from various brands, including Mechanic, 3M, and others.

Local auto parts stores: Physical retailers like Blade Auto Center and specialized car accessories shops often carry specific tapes for automotive use, such as exhaust wraps and foil tapes.

Industrial suppliers: For specialized, high-performance tapes, industrial processing or equipment suppliers may offer a broader selection with different backing materials and adhesives.

How to apply exhaust wrap tape

Prepare the surface: Ensure the exhaust system is cool. Clean the surface thoroughly to remove dirt, oil, and rust, which can affect adhesion and overall performance.

Soak the wrap: Wetting the fiberglass or ceramic wrap makes it more pliable and easier to work with. Do not soak it excessively.

Start wrapping: Begin at the end of the pipe farthest from the engine. Overlap each revolution of the tape by about 25% to ensure complete coverage. Maintain consistent, tight tension.

Secure the ends: Use stainless steel locking ties or wire to secure the tape at both the beginning and end of the wrap.

Cure the tape: Run the engine to allow the heat to cure the tape and set the adhesive. Some smoke and odor during the initial curing is normal.